Existing Conditions

This building is fitted with conventional compression taps with rubber washer seals. The taps are often leaking and require frequent replacement of the seals, indicating that the valve stems and seats are worn out. The fixtures need replacement.

Retrofit Conditions

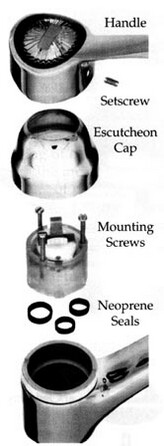

Replace the existing fixtures with washerless models to reduce leakage and eliminate wearing of the most expensive parts. When these fixtures develop leaks, which is much less frequently, the repair is a simple cartridge replacement. A new cartridge restores the unit to "like new" operation. The main components wear very slowly, so the lifespan of the fixture is longer.

We do not recommend sensor-activated faucets in commercial applications, as they have been shown to create more water use than standard push-top or swivel taps.

Further Benefits

Maintenance labour decreases due to the increase in fixture lifespan.

The reduction in wasted water lowers municipal water and sewage service costs.

Application Details

Replace fixtures only when they are at the end of their lifespan. The cost for washerless fixtures is 30-50% higher than comparable compression units. The increased cost is expected to pay back in one to four years, based on reduced leakage.

A good way to detect leaking fixtures is to monitor your water meter during times when you would expect no water use (1:00 a.m. - 5:00 a.m. in family & seniors buildings). Substantial overnight water consumption may indicate that toilets, taps or bath/shower fixtures are leaking.

Include twice yearly inspection and replacement of all tap washers in the preventive maintenance schedule.

Some leaks are so large, they are audible.

Issues and Concerns

Make sure to examine the warranty to understand coverage of parts. Repairs can require replacement of a complete valve cartridge at a cost of about $10 per valve.

Use only steel or stainless steel units. Washerless taps made of chrome plated ABS plastic will not stand up to regular use as well as the equivalent metal part.

Flow restrictor should not be placed on utility of laundry taps. The resulting low flow for filling buckets will produce complaints.

References

Millenium Dome Report on Water Efficiency-“Watercycle” (2002), http://www.cuwcc.org/WorkArea/showcontent.aspx?id=2130

Analysis

Analysis text here