Existing Conditions

The garage exhaust fans run <constantly> <on a long schedule>, to limit the concentration of poisonous carbon monoxide (CO) gas in the garage area and prevent it from migrating into occupied areas of the building. However, much of the time the fans are running when there is no risk of vehicle exhaust build-up. During those times, the fan motors are consuming electricity unnecessarily <and, because this is a heated garage, heat is being thrown away in the exhaust air stream>.

Retrofit Conditions

The simplest way to reduce fan operating hours and save energy would be to install timeclocks. However CO will accumulate if a vehicle is operating in the garage during a period when the fans are off. <In fact the Ontario Building Code (OBC) dictates that unless there is a CO monitoring system, garages must have a continuous ventilation rate of 3.9 Litres per Second (l/s) per square meter of floor area.>

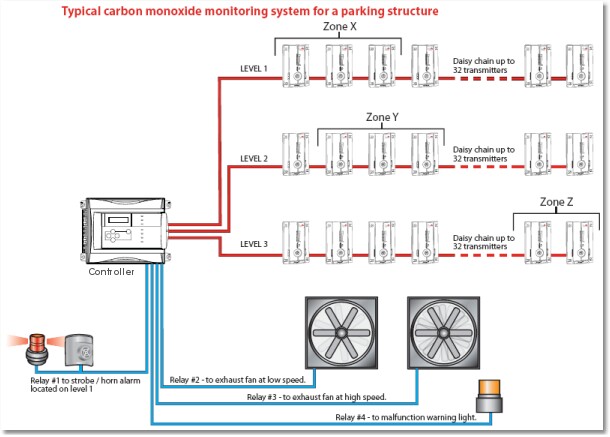

We recommend installation of a CO monitoring system. The system will measure the levels of CO gas in the garage area and activate the fans when a pre-established gas concentration (in the range of 100 parts per million) has been exceeded. In this way, the exhaust fans will operate only when they are really needed to maintain air quality in the garage.

A network of CO sensors, centrally monitored, is used to activate fans and alarms. These systems can be integrated with building automation systems.

Further Benefits

Garages below grade will tend to be warmer and less drafty, since overall air exchange is reduced.

Application Details

In principle, this is the most efficient method of controlling parking garage ventilation, and is particularly cost-effective in heated garages. In those applications, the savings in heat far exceed the fan motor electrical savings. Regardless of the method employed to control garage exhaust, owners of heated garages should pay careful attention to the heating control. Remember that garage heat is intended for freeze protection of wet sprinkler systems and to provide a bit of comfort on extremely cold days. Garage users are in transit between the conditioned space and their vehicles, are dressed for outdoor conditions, and should not expect full comfort conditioning.

Engineering design procedures are available on the Honeywell Vulcain web site.

Issues and Concerns

Annual sensor testing and calibration is strongly recommended and should be budgeted.

References

Analysis

The fresh air exchange in a garage can be estimated using the CO emission from the vehicles in the garage.

qCO = (20 + 0.1 l1) c1 + 0.1 c2 l2 (2)

where

qCO = CO emission (m3/h)

c1 = capacity of parked cars in the garage

l1 = mean driving distance for cars in the parking garage

c2 = numbers of cars driving through the garage

l2 = mean driving distance for cars driving through the garage

The required fresh air supply can be estimated with

Q = k qCO (3)

where

Q = required fresh air supply (m3/h)

k = application coefficient

The application coefficients used are

k = 2 where people are in the garage temporarily

k = 4 where people are in the garage permanently - service shops or similar

Example - Fresh air supply to a garage

A Storage (Parking) Garage

The fresh air supply to a storage garage with 10 cars, floor area 150 m2, volume 300 m3 and a mean driving distance for the cars of 20 m, can be calculated as:

Required air changes per hour

Fresh air supply due to air change requirement of 4 per hour can be calculated as

Q = (4 1/h) (300 m3)

= 1200 m3/h

CO emission

CO emission can be calculated as

qCO = (20 + 0.1 (20 m)) (10 cars)

= 220 m3/h CO

Required air flow due to CO emission can be calculated as

Q = 2 (220 m3/h)

= 440 m3/h air

Comparing the two calculations - the fresh air supply should be 1200 m3/h.

For a very rough calculation, many jurisdictions including Ontario mandate a design air flow of 500cfm per parking space in an enclosed garage.